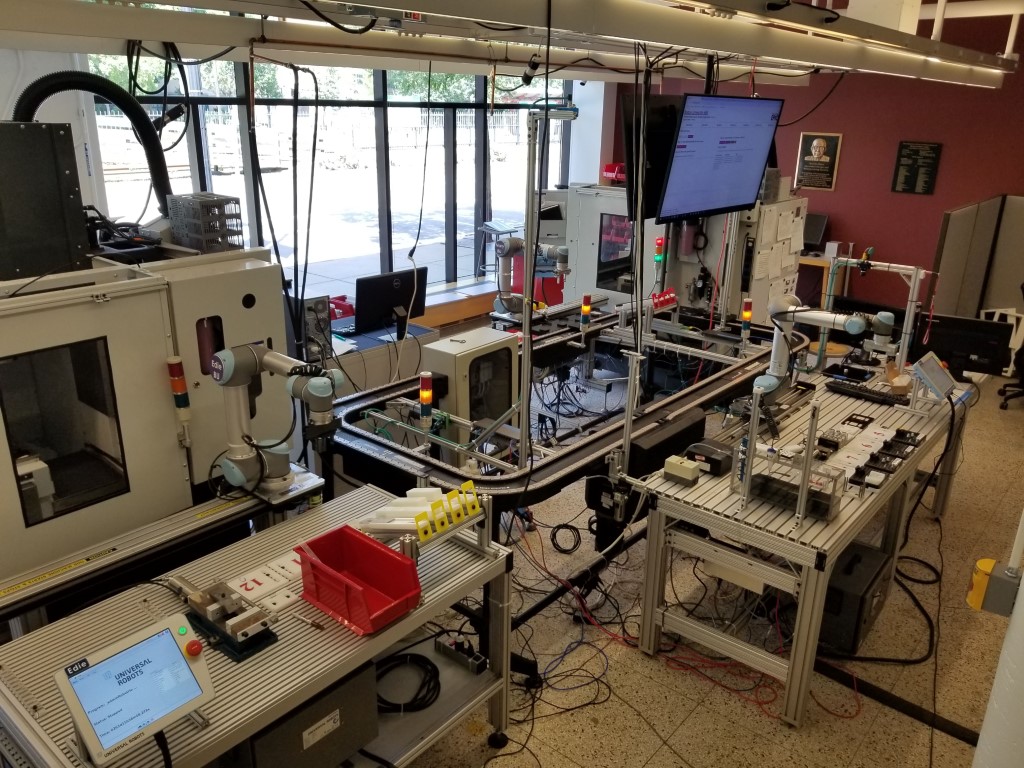

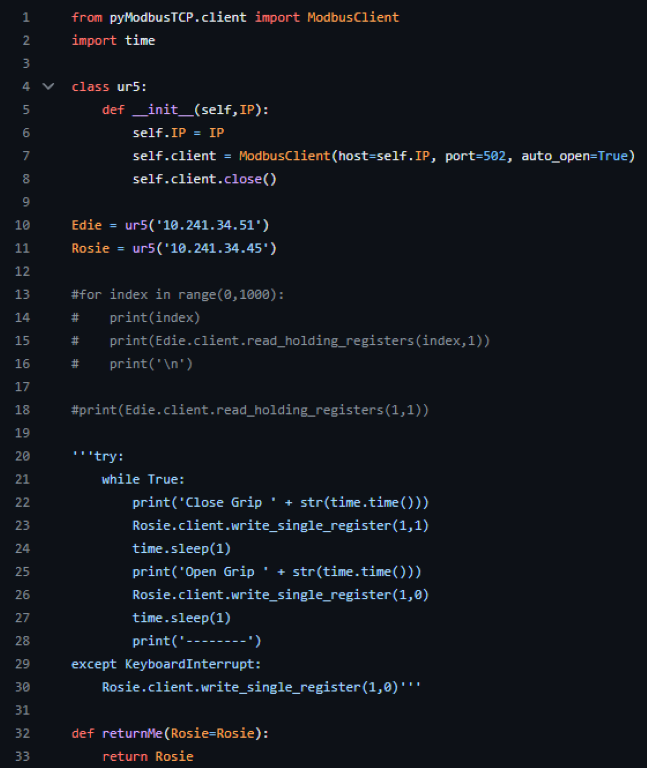

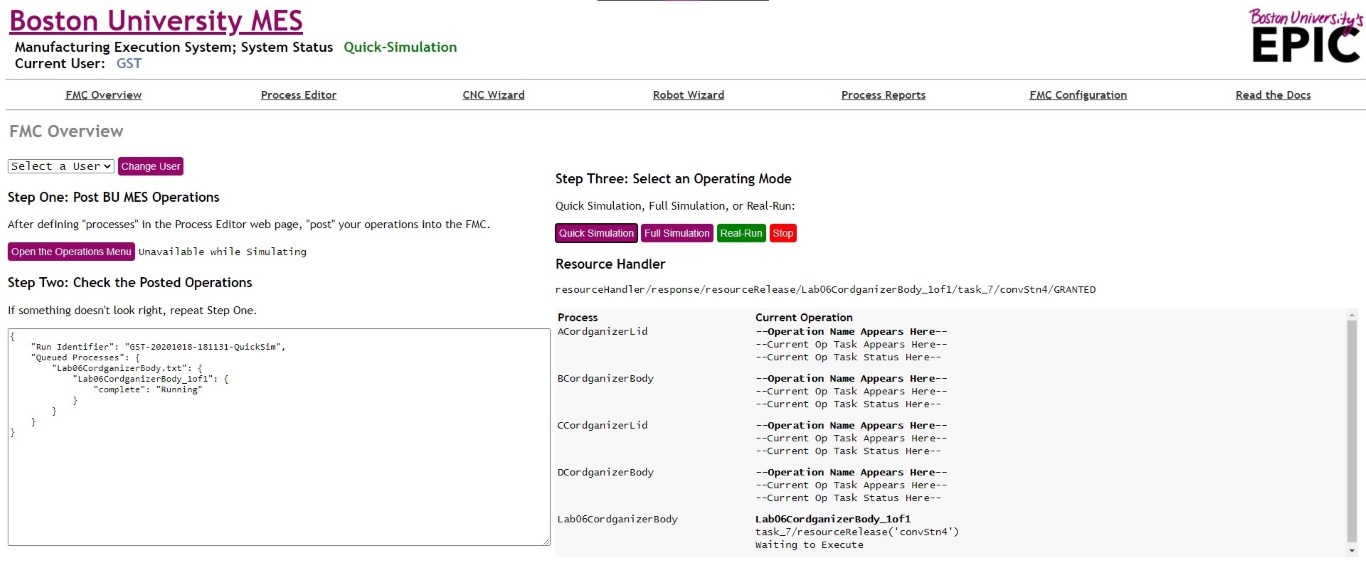

Within a semester, this project exploded from a single Python script into a full-blown web

application. It was dubbed "BUMES," the Boston University Manufacturing Execution

Software. There were multiple user interfaces, each showcasing a different aspect of

automation. Each of the nine laboratory exercises directly into the interface using familiar

keywords. The

software collected execution times and other data for students to process. Eventually, I even

hired

and managed two brilliant computer engineering students to further improve the software and

give it

a polish.

See more of the BUMES interface by downloading an example lab manual:

Computer Integrated Manufacturing I

Computer Integrated Manufacturing II

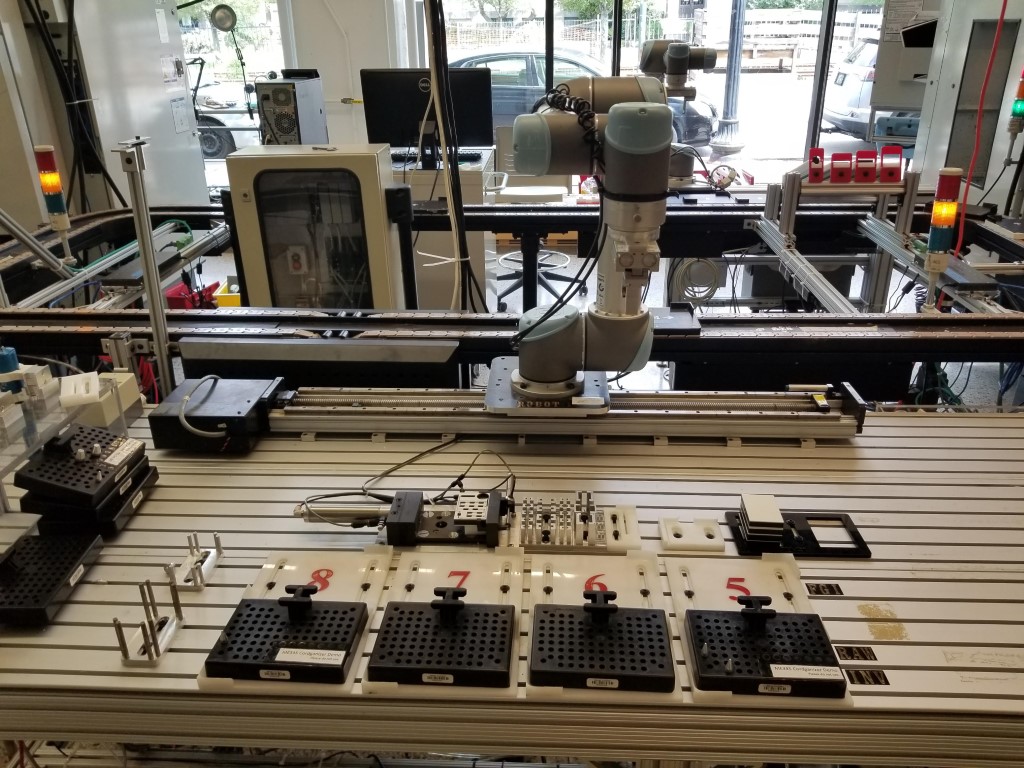

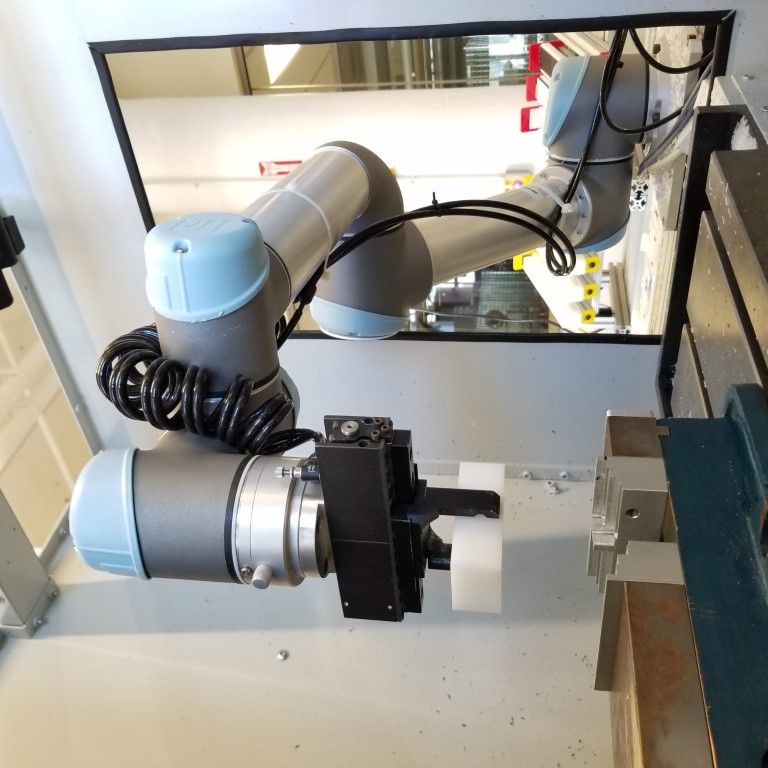

When I reflect on my time at BU and in the ADML, I find it very challenging to express the number of

lessons learned as part of this work. There

were weeklong trials learning everything from how to write loops in G-Code to debugging

CAN

networks

to writing ASCII text commands for the oldest PLC I've ever used. I have a newfound

appreciation for the challenges of attaining reliable automation, both in hardware and software.

As is inevtiable when embarking on these journeys, there is much that I would go back and redo.

However, as of writing, I am pleased to hear the software is still used today to teach

students. Continue scrolling here to view some videos. See more of my sidequests in the ADML

on my Noteworthy

Projects page under the "Work" section.