Personal Projects

A random assortment of personal projects.

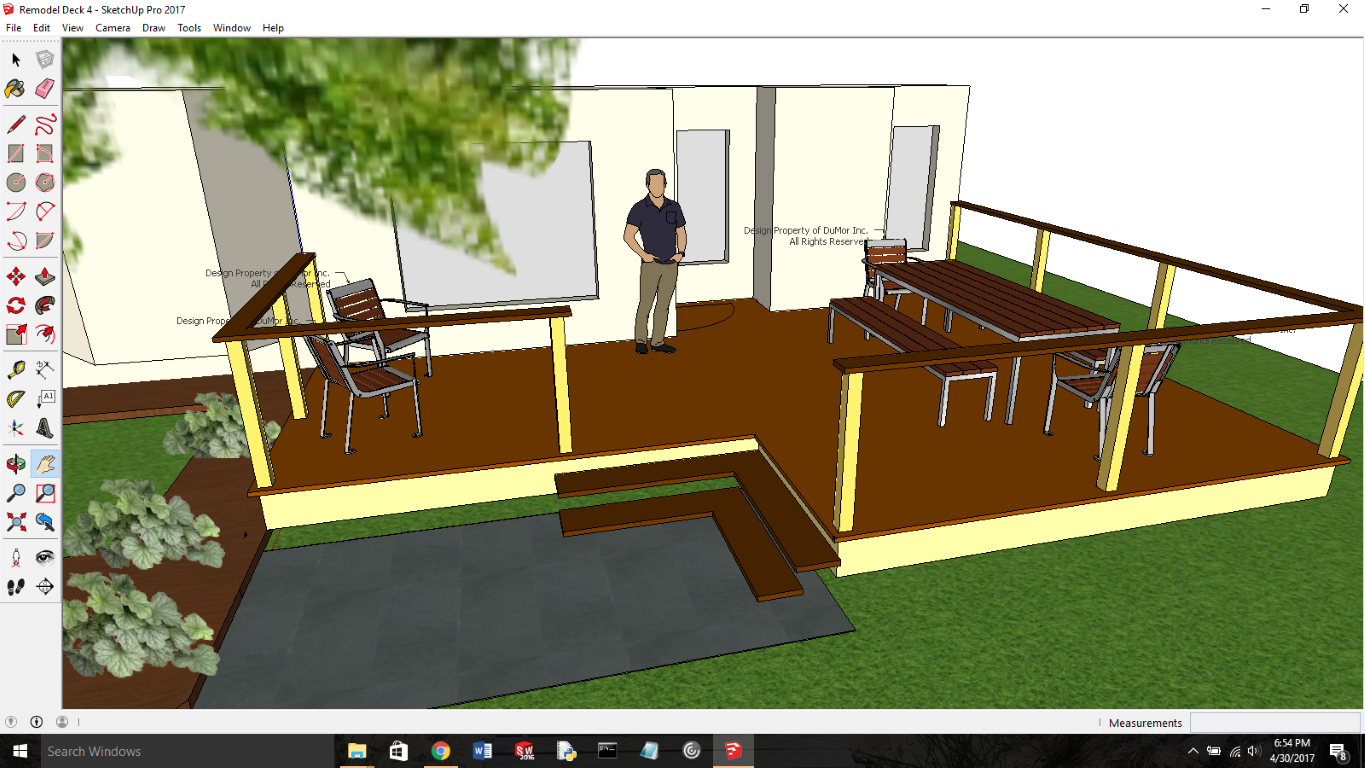

A New Deck for My Parents

Summer 2017

Immediately after graduation, I was still job hunting. In the meantime, my parents asked for a pretty major deck overhaul. I took this as my excuse to learn Sketchup! I used the design to meticulously shop for material and construct the new deck.

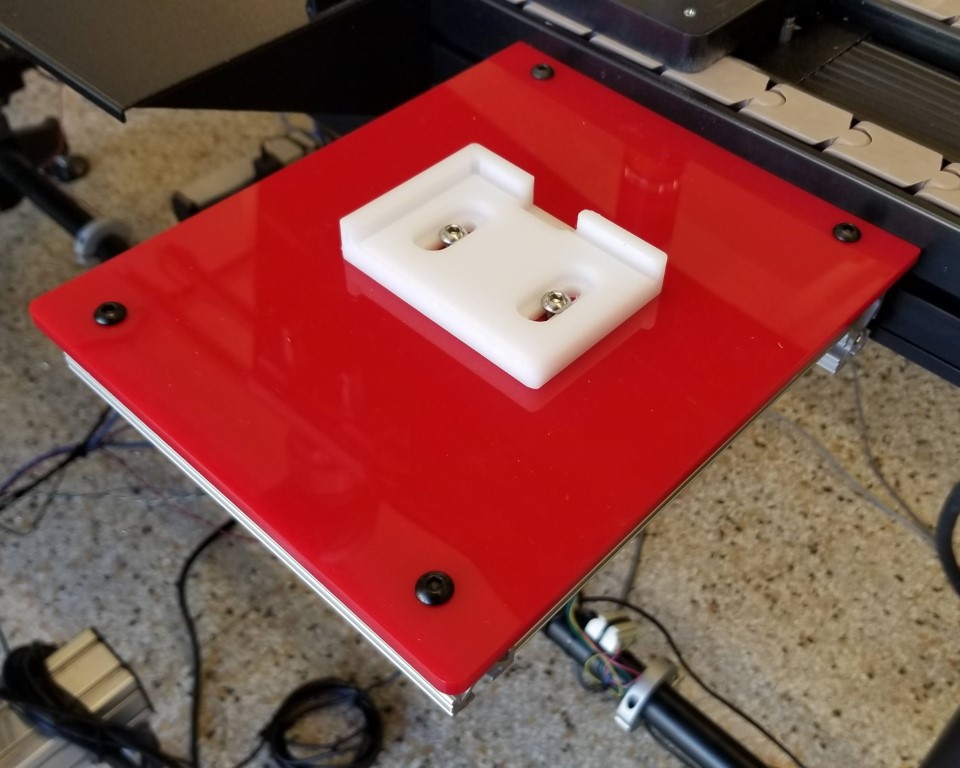

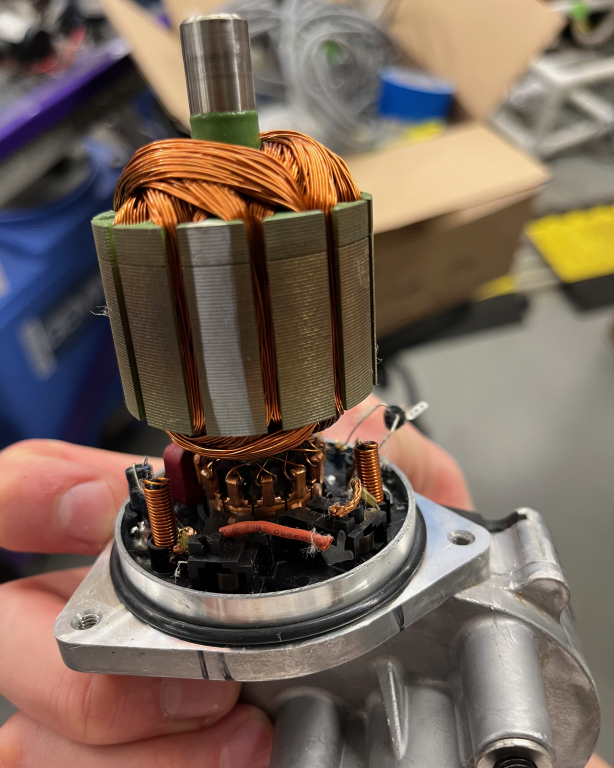

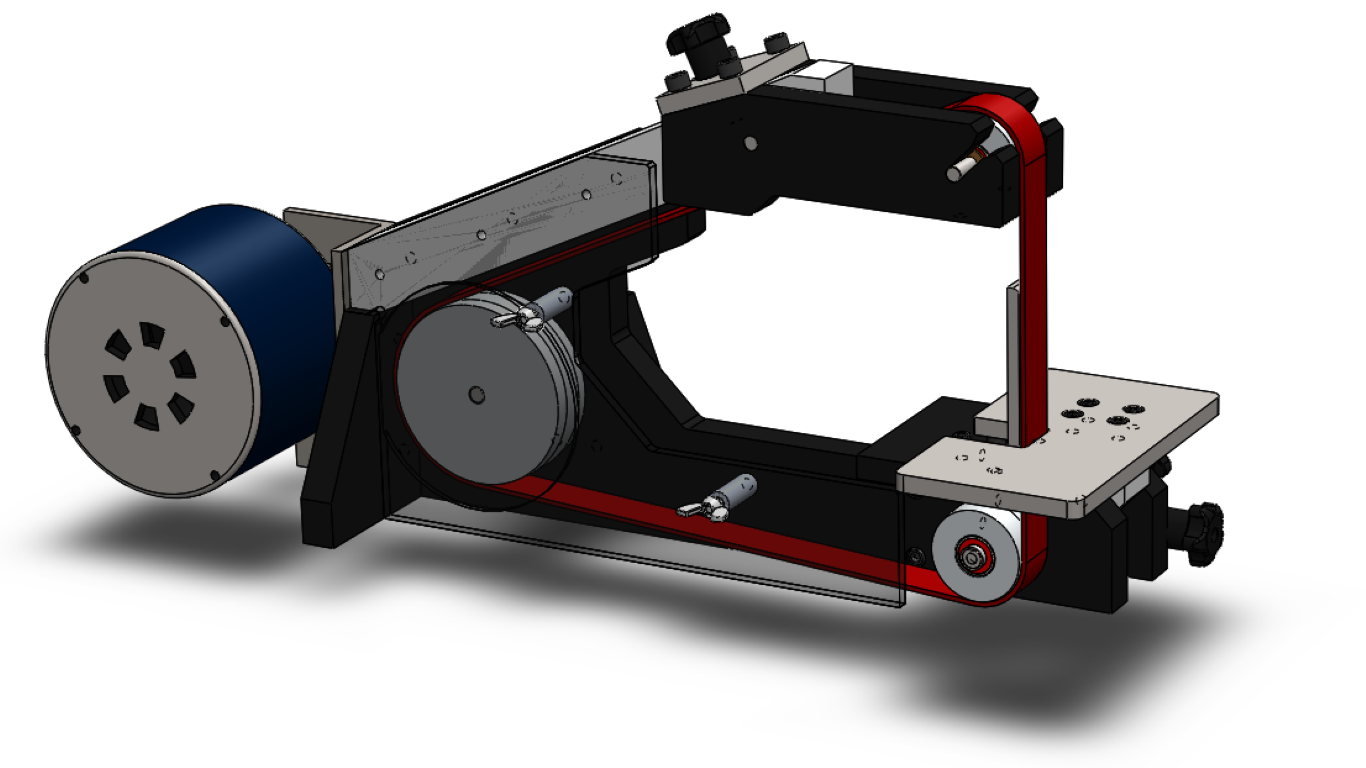

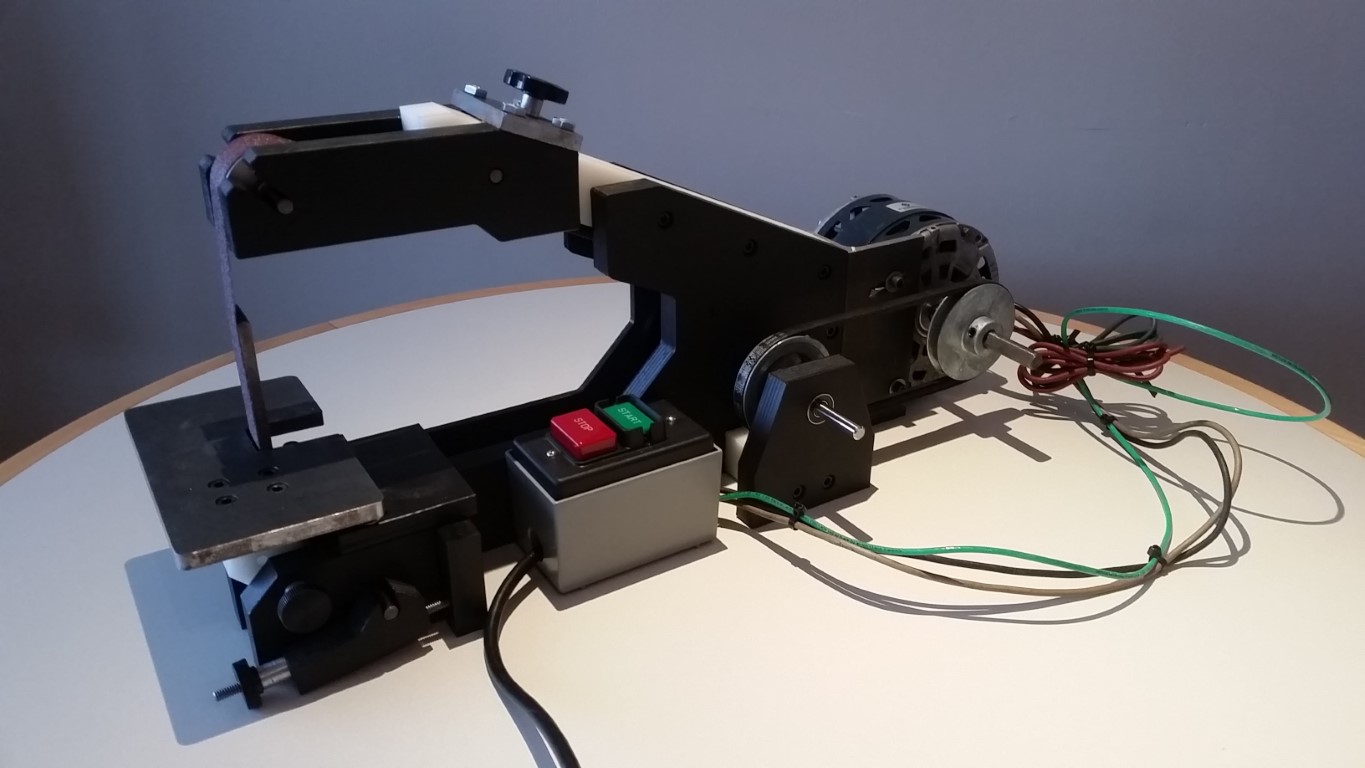

1" x 42" Strip Sander

Spring 2017

Inspired by a youtube video by Matthias Wandel, I designed this strip sander for fun.

I later convinced the BU department of engineering that building this sander should meet the requirements for my undergraduate manufacturing concentration. Fortunately, they accepted!

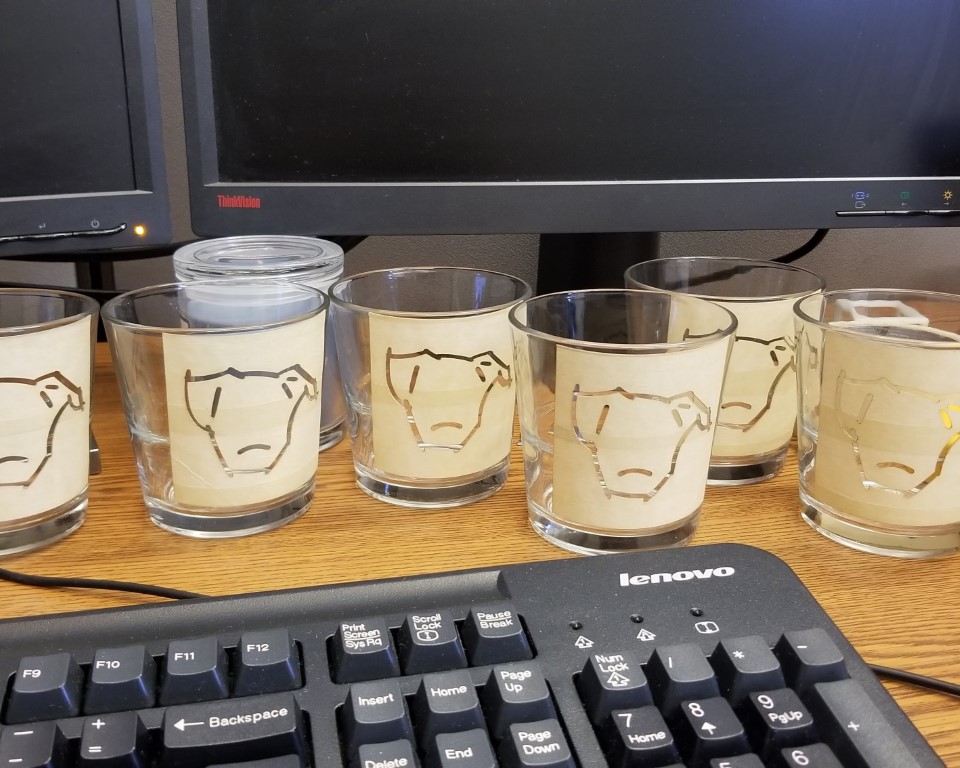

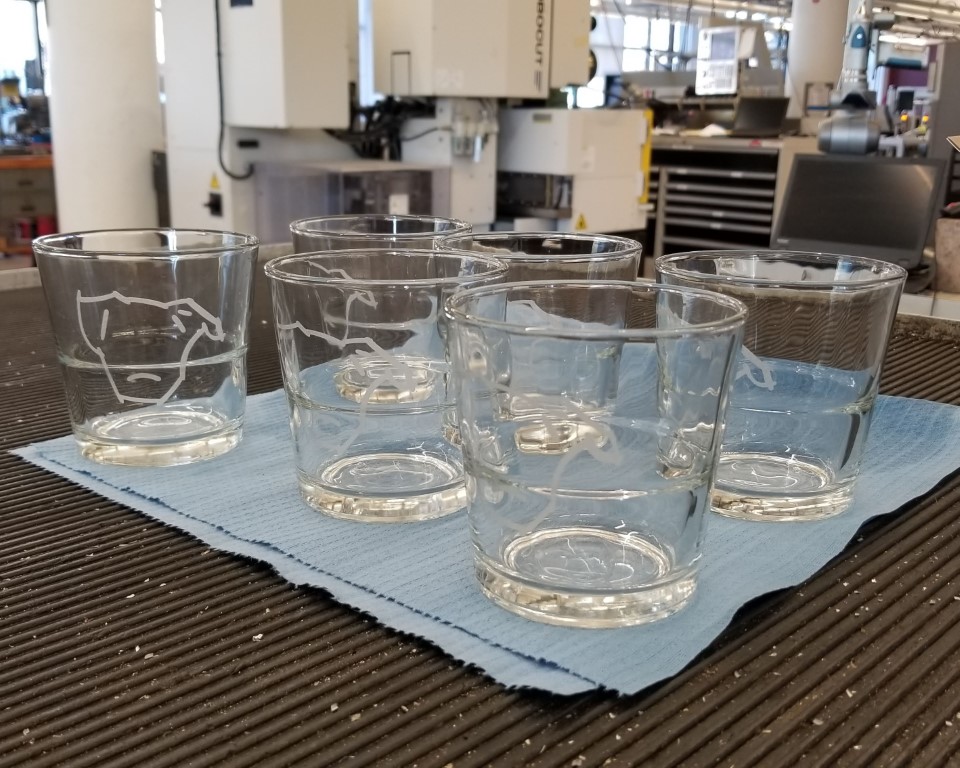

Engraved Glasses for a Friend

Winter 2019

Using my iPad, I traced the outline of a photo of a friend's dog. I exported that image, laser cut some special stickers, and media blasted the sketch onto a set of glasses as a Christmas gift.